Silicone Mold Repair

Arizona Tool & Plastics offers expert silicone mold repair services. We provide the following types of service:

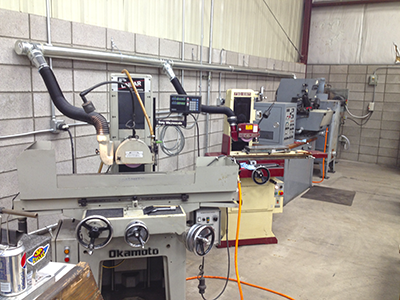

- Re-machining mold surfaces, using our assortment of milling machines, surface grinders, lathe, and electrical discharge machining (EDM)

- Welding – MIG & Micro Welding

- Polishing: removal of undercuts, bringing back to original finish specification.

- Sand blasting: to provide a non-smooth textured type finish.

- Cleaning of heating system/cartridge heaters & thermocouples. Re-apply heat transferal grease.

- Replacement of wear items: leader pins & bushings, ejector pins, parting line locks, cam pins, wear plates, gibs, pneumatic/hydraulic cylinders, hand loaded inserts, etc.

- Re-sharpen Parting Line edge: micro/laser welding

- Re-vent parting lines, including overflow pull-off tabs.

- Repair gating: inserts or welding, EDM gates per specification.

Diagnose, repair, and “as needed”, replace parts to fix Cold Deck System issues.